Founded as a brand in 1983, but in operation since the mid-1950s, Marvic Wheels’ range of services stretch far wider than ‘just’ wheels. Using innovative sand gravity casting technology, it produces high-quality magnesium wheels for cars and bikes, and other stressed automotive parts, many of which have been instrumental in motorsport successes in a number of disciplines. Almost the whole production process is done in-house at the firm’s factory close to Varese in Italy. Our photographer Rémi Dargegen took a trip to speak with Marvic’s CEO, Pierluigi Sturla.

What’s your earliest automotive memory?

When I was five- or six-years old, my parents ran a luxury car dealership in Milan, and I was often enchanted by the sinuous shapes and the ever-broadening range of colours. I remember being emotionally overwhelmed by the sound and speed of my father’s Ferrari 512BB, and the excitement of our trips to the Toce Falls with his 1928 Bentley.

Is that when your passion for cars began?

Indeed. When I was five, my parents bought me both a miniature Mercedes Pagoda and a Jeep to get around the woods – both were powered by internal-combustion engines. The only gifts I ever asked for were model cars, particularly classics, which thrilled me the most. I then began karting aged seven.

Italy and cars go hand in hand – did living in the country help to grow your passion?

A famous magazine in the late 1960s once defined Italian cars as the most provocative things in the world after Sophia Loren. Need I say any more? The greatest excitement and stimulus for me today is in manufacturing special wheels and components for the cars with which I used to play as a child.

Was it a natural progression for you to start working in the company?

Unfortunately my grandfather passed away when I was young, but this cruel reality opened my eyes to his world of work – and I’ve never imagined doing anything else since. I always remember being at the racetrack, and my grandfather’s enthusiasm at testing new products and gaining approval from the teams using them. The feeling is exactly the same for me now, though I regret that he never got the chance to witness me using everything he taught me.

Tell us about the beginnings of Marvic Wheels?

The foundry was opened in 1954, for the production of aluminium, bronze and brass castings. Then, in the mid-1970s – when customers already included Osella, Dallara and other notable names in the automotive field – my grandfather travelled to England to study magnesium alloys. In 1983 the Marvic brand was founded, and with it came the world’s first wheel with elliptical hollow spokes. In the motorsport world, it was an innovative invention, and in less than two years, 90% of all racing bikes were fitted with Marvic wheels. Nowadays we’re a specialist in magnesium and aluminium alloys, and produce wheels and components both in small numbers and larger series, for various applications in the automotive, motorcycle, aviation and textiles industries.

Today, you’re the CEO of the company, but how did you learn your craft?

I never enjoyed academic life, so chose to study on-the-job by joining the company straight after finishing my diploma. I paid my dues in each department, and I’m proud that I can now work in every phase of the production process – well, apart from the office! My favourite quote to live by belongs to Carroll Shelby. He said, “If you don’t do what you wanna do, you’re bullshitting yourself.” I’m convinced that the most important thing is passion, and anyone can better themself by truly believing in what they do.

Could you explain a little more about the design process?

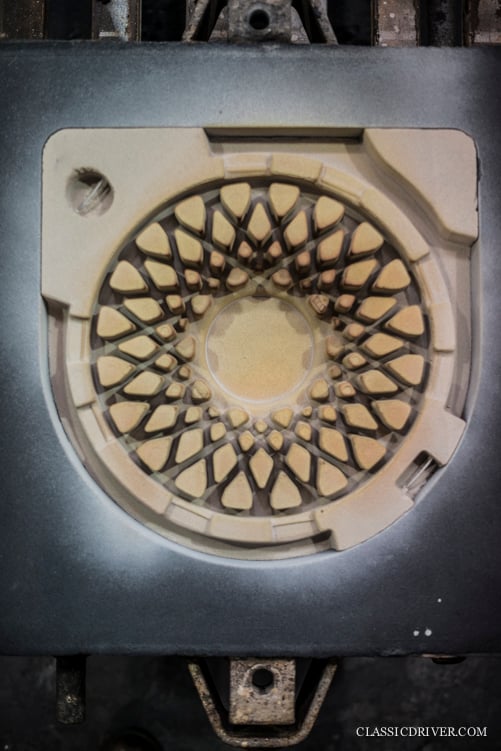

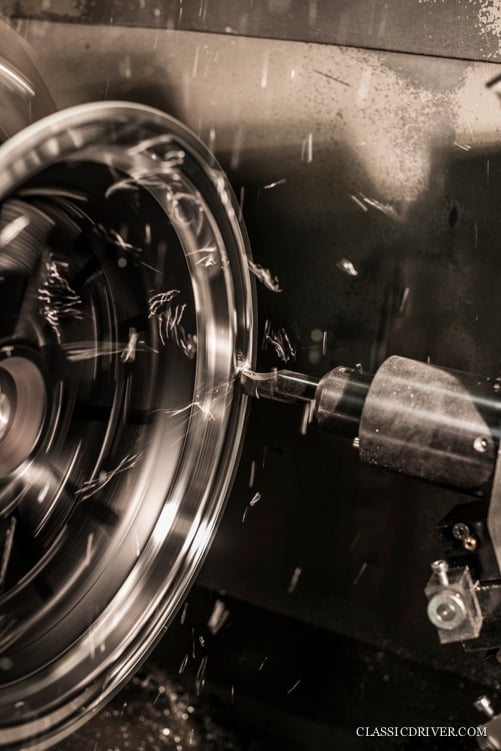

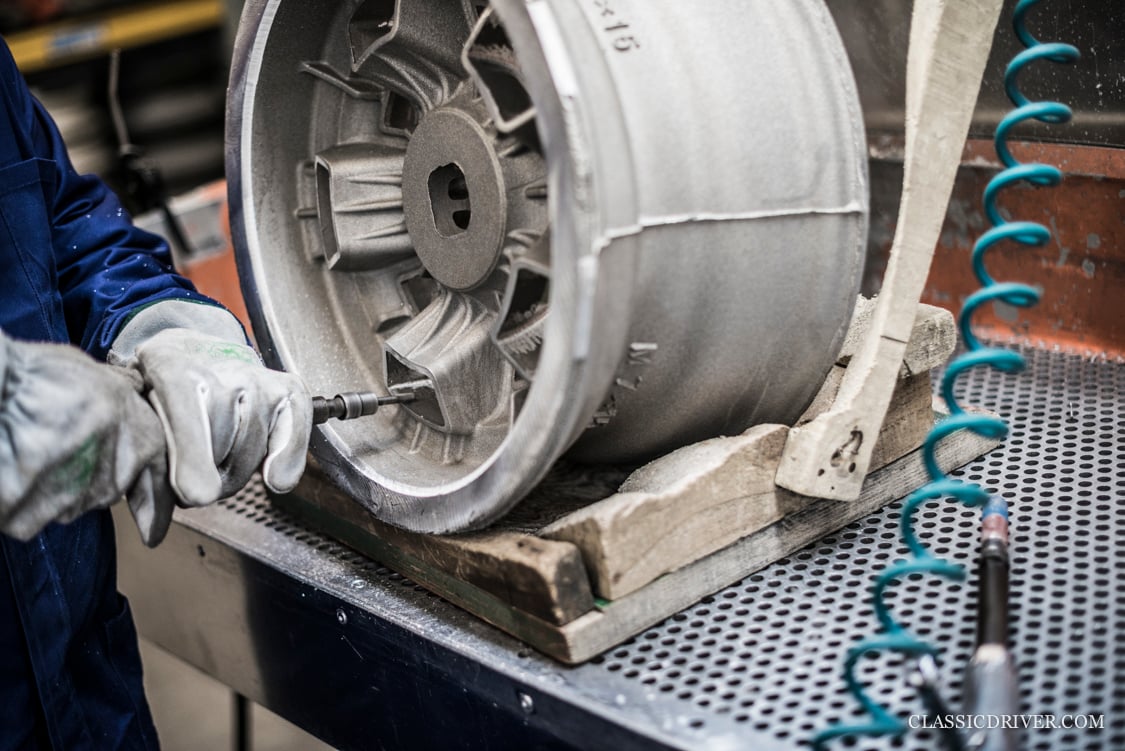

Everything is done internally at Marvic Wheels, which gives us complete control. Projects start as either a drawing or a sample to be replicated. In the case of the latter, a 3D optical scan is made and, by way of reverse engineering, drawings can be prepared. Once the tooling is engineered (a vital step), production is done either by hand or with semi-automatic machines, with the use of green or resin sand. A test bar is produced for destructive testing to check the quality and properties of the alloy, before the component is de-burred and blasted prior to heat treatment. Machining is then carried out on milling machines and CNC lathes. The passion and craftsmanship are still tangible all these years later – just as my grandfather would have wanted.

Recently, you posted a photo of Roberto Bertaccini from Cremonini Carrozzeria and Valentino Balboni. How do you know them?

I met Valentino and Roberto for the first time just a few months ago and, thanks to a mutual friend, was able to collaborate with them on a project concerning Lamborghini Miura wheels. Even though I’ve not known them for very long, their commitment and passion is a joy to behold, and to know that they appreciate my work makes me very proud.

What range of products do you provide?

We manufacture castings ranging from 30 grams to 700 kilograms in weight. The uses for magnesium castings are countless – from machines for printing, to processing tobacco. Its ability to absorb vibration makes it the perfect material for mechanical parts that are subject to sudden changes in direction – hence why we make wheels for motorcycles and historic racing cars, and bell housings, uprights and steering arms for GP2 and LMP cars.

What does the future hold for Marvic Wheels?

Chasing classic cars – as I mentioned earlier, my heart beats faster for them. My vision is to broaden our catalogue. There are a number of things we’re working on, so stay tuned…

Do you also drive a classic car?

I’ve had several cars over the years but never a classic, purely for economical reasons. The oldest car was a Mini Cooper 1300 running on carburettors – selling it was a huge mistake! I’ve always been crazy about lightweight sports cars, and I currently own a Caterham.

Regardless of cost, what would be your dream car?

The list would be rather long, as it’s impossible to choose just one. For special events and having fun on the racetrack it would have to be the Porsche 917, for enriching that summer road trip to Lake Maggiore I’d choose a Cobra 289, and for daily life I’d use a Ferrari 250 GTO. That might sound extravagant, but remember: only small minds think dreams are too big.

Photos: Rémi Dargegen for Classic Driver © 2016